Nexeed Manufacturing Execution System

The MES from Bosch

Nexeed Manufacturing Execution System

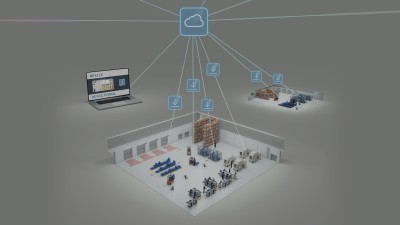

Transparency in real-time is the basis for successful optimization, planning and control of production. The Nexeed Manufacturing Execution System provides exactly the information companies need for an active control system, seamless documentation, tracking, quality assurance and control of their production along the entire value stream. The goal is to continuously optimize processes based on this data, to respond to changes quickly. Accordingly, this brings about an increase in production efficiency. The Nexeed Manufacturing Execution System ensures vertical integration, in particular, ranging from the sensor all the way to the cloud. Consequently, the solution represents the link between the machine control system and the ERP systems.

Fields of application

-

Operating data and machine data collection -

Operating equipment management -

Information management -

Material management -

Planning and process control -

Shopfloor integration -

Quality management & traceability

Benefits at a glance

The modular, scalable Nexeed Manufacturing Execution System is as flexible as the respective customer requirements and can always be expanded according to the specific production requirements. From the starter kit to the fully integrated MES – each company decides for itself what the level of detail and application area will be.

Transparency throughout the value chain

Increased output and productivity

Visualization of production information in real-time

Modular software solutions for flexible production

Independent of products and machines

Global service and training

Automating manufacturing processes powered by Bosch